The Chroma 17010 Battery Reliability Test System is a high-precision solution designed specifically for testing lithium-ion battery (LIB) cells, electric double-layer capacitors (EDLCs), and lithium-ion capacitors (LICs). Ideal for product development and quality control, the system offers a comprehensive suite of capabilities for characterization, cycle life testing, and product screening.

Choose between the linear circuit series for minimal output noise and exceptional measurement accuracy during development of small and medium-sized energy storage components, or the regenerative AC/DC bi-directional series for standard product life evaluation and testing of larger energy storage components and power batteries, all the while saving power and generating minimal heat.

The Chroma 17010 streamlines your testing pipeline with its powerful Battery LEx software platform. Access a library of predefined test recipes or easily create your own with the multi-layered recipe structure. Edit and modify projects on the fly, manage individual DUT data, and leverage shared recipes for efficient testing across different battery types.

Battery LEx goes beyond traditional charge/discharge testing by incorporating C-rate, OCV-SOC, Q%, waveform simulation, and chamber control modes.

This facilitates compliance testing to international standards (USABC, IEC, GB/T) and supports an array of other test applications. The user-friendly group management interface lets you effortlessly track test status and execute various controls like skip step, pause, scheduled pause, specified start, and resume test.

The Chroma 17010 system can be slotted with high-precision, multifunctional data loggers that capture the temperature, voltage, and pressure of the DUT in real time. Besides enabling advanced cutoff and protection conditions, this also supports seamless integration with climate chambers of a variety of brands. Directly control the chamber by issuing chamber control step commands, complemented by b u i l t - i n chamber synchronization and secondary adjustment functions for optimal convenience.

The Chroma 17010 prioritizes safety with a robust, three-tiered approach: software/hardware detection, equipment abnormality monitoring, and optional independent relay hardware detection, guaranteeing protection for both user and equipment throughout the testing process.

Ultra High Precision Charge/Discharge Tester 17208M-5-12C

The Chroma 17208M-5-12C is an ultra-high precision programmable charge/discharge tester specifically designed for precision measurement applications such as Coulombic Efficiency (CE) analysis, Incremental Capacity Analysis (ICA), and Differential Voltage Analysis (DVA). Applications like these call for instruments capable of measuring battery voltage and capacity for an extended period with high levels of stability, precision and accuracy, thereby obtaining high-quality test data without any need for post-processing. The Chroma 17208M-5-12C goes above and beyond by offering four current ranges (12A, 4A, 0.4A, 40mA) and a 0-5V voltage measurement range for charge/discharge. To ensure optimal measurement quality, each channel is equipped with shielded wiring to isolate the equipment from noise.

Best-in-class Stability, Precision, and Accuracy

Through meticulous structural and circuit design, the 17208M-5-12C effectively mitigates the impact of waste heat on its high-precision circuits and components, improving measurement stability during longer tests. With a measurement accuracy of up to ±0.01% of F.S. (Full Scale) and precision of up to ±0.001% of F.S., this tester reliably delivers consistent and repeatable test results.

• ±0.01% of F.S. measurement accuracy

• ±0.001% of F.S. measurement precision

High Resolution, Low Output Noise

The 17208M-5-12C employs a 24-bit ADC to enhance measurement resolution, providing highly granular test data that accurately reflects the DUT's actual electrical signal.

• Voltage measurement resolution: Up to 1μV

• Current measurement resolution: up to 0.01μA

Simplified DVA Test Data Processing

Differential Voltage Analysis (DVA) is commonly used to assess battery aging. However, poor measurement accuracy and precision can make it difficult to identify characteristic peaks, often requiring extensive resources to run smoothing algorithms and risking curve distortion. The 17208M-5-12C delivers stable full-range current output throughout the test. This ensures accuracy and minimizes noise from measurement fluctuations, resulting in DVA curves with clearly identifiable characteristic peaks.

17010 Series

Multiple Current Range Design

Quick switching of current ranges

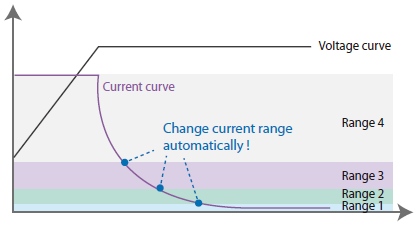

The Chroma 17010 series enables switching between multiple current output and measurement ranges to accommodate test plans with both high and low currents. At the start of each test step, the system detects the output current and then quickly switches to the appropriate current range automatically. This boosts the test's accuracy as well as its resolution, yielding quality test data you can trust.

Automatic range switching under constant voltage (CV) mode

The linear circuit models of the Chroma 17010 family support automatic switching between current ranges during testing in CV mode while maintaining uninterrupted output. This is ideal for applications like float charging and potential regulation, which require long-term and highly stable testing at very low currents.

DST Application Test & Current Range (Using 17216M-6-12 model range)

CV Test Current Switching

High Stability Long-term Output

The Chroma 17010 is engineered for low output noise and superb measurement accuracy. Capable of converting test current and voltage data into highly accurate and distinct characteristic peaks, the 17010 enables you to investigate the aging mechanisms of your Li-ion batteries with unprecedented efficiency.

Actual Voltage/Current Measurement Accuracy

Differential Voltage Analysis Curve

High-speed Sampling Technology

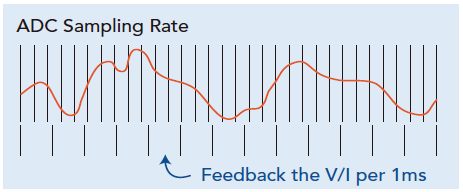

Conventional battery cyclers typically record key data at report sampling speeds, which produces significant cumulative error over time. The Chroma 17010 addresses this by utilizing high-speed voltage and current sampling with double-integration computing. This enables the system to accurately capture transient changes during testing without loss, resulting in highly reliable capacity calculations.

• Hardware internal voltage/current sampling rate: 1mS

• Report single point transient sampling rate: 1mS

• Report sampling rate: 10mS

General Testers Charging/Discharging Sampling Rate

Chroma 17010 Charging/Discharging Sampling Rate

Super Mode: 120% Charge/Discharge Output

The regenerative models in the 17010 family offer wideranging power and current coverage with their Super Charge/ Discharge Output functionality. Super Mode allows you to easily configure and run up to 30 seconds of 120% current or power directly within your test steps, ideal for an array of high-current pulse test applications.

• 17212M-6-100S: 120% CC and CP charge/discharge output

Hybrid Pulse Power Characteristic (HPPC)

Fast Current Response (<1mS) for Optimal Realism

Besides Super Mode, the regenerative models also boast a current ramp-up time of less than 1mS. This enables more accurate simulation of the battery's instantaneous peak currents during on-road charging and discharging, meeting test data requirements for standards such as NEDC, FUDS, and DST.

• 17212M-6-100S: 10% to 90% < 1mS

0~1200A Current Rise Time <1mS

Three Voltage Ranges

The Chroma 17216M-10-6 model offers three voltage ranges selectable via software, offering extra versatility for various product development applications.

• 0V to 5V: Half-cell, full-cell, EDLC

• 0V to 10V: Series batteries, EDLC

• -5V to 5V: Symmetric batteries

Dynamic Waveform Loading

The Chroma 17010 goes beyond basic battery cycling by enabling you to preload dynamic charge/discharge waveforms. Evaluate your batteries’ degradation modes and cycle life with enhanced realism by using dynamic current or power waveforms that closely mimic on-road charge/discharge conditions such as acceleration, deceleration, and uphill or downhill driving.

• Supports dynamic and fixed time modes (min. output interval 10ms)

• Dynamic preloading of up to 6,400,000 data points per system

Dynamic Waveform Simulation

Energy Recovery Architecture

The high-current models in the 17010 lineup feature highprecision, high-efficiency, and power-optimized energy recovery architecture, purposely designed to minimize waste heat generation during discharge and empower sustainable approaches to battery test.

• DC: Automatically prioritizes transferring discharged energy to charging channels with >80% recovery efficiency.

• AC: Excess energy is recovered back to the AC mains with >60% recovery efficiency.

• Current is fed back to the grid with <5% total harmonic distortion (THD).

Energy Recycling Architecture

Ripple Output

Chroma's ripple current test solution involves superimposing an AC current with a frequency between 100Hz and 20kHz onto the 17010 system (model 17212M-6-100S). This allows you to simulate the behavior of an electric vehicle (EV) inverter or the heating effect of AC current delivered from a charging station (EVSE) to the battery.

• Ripple frequency from 100Hz to 20kHz, amplitude up to 75App, and up to 150App in parallel (customizable)

• Independent AC and DC circuits, minimizing impact on DC charging and discharge cut-off judgment

• Ripple current superimposition in various CC, CV, and CP charging and discharging modes

Parallel Current Output

The entire Chroma 17010 series supports dynamic parallel functionality, allowing idle continuous channels to be paralleled for higher current output. This feature not only enhances testing versatility but also accommodates a wider variety of test applications.

Data Protection & Recovery Function

Experience peace of mind with Chroma 17010's robust data protection and recovery functionality. Enabled by an optional UPS (uninterruptible power system), this feature enables the system to temporarily store test data in the IPC database during power failures. After the power issues are resolved, the 17010 automatically retrieves the data state and resumes testing from the point of interruption, ensuring seamless data continuity.

System Integration and Protection

The Chroma 17010 supports integration with environmental chambers of various well-known brands as well as multifunctional data loggers. With the Battery LEx software, you can set parameters and monitor data simultaneously. Test data is automatically compiled into test reports, all in all providing a fully comprehensive test solution.

Data Logger Integration

• Can record temperature (°C), voltage (V), pressure (mPa), or force (kg).

• Recorded real-time data can be used as judgment criterion for cut-off or temperature protection measures.

System Protection and Abnormality Detection

• Test recipes include various built-in protections; the protection mechanism monitoring these has a response speed of 1mS when triggered. An optional external voltage/temperature meter relay can be added to provide reliable dual-layer protection.

• Real-time abnormality detection allows each individual unit to automatically detect abnormalities based on independent logic. When the system is interrupted, the test can be continued after the exception is cleared without data loss.

Chamber Integration and Peripheral Safety Engineering

• The Battery LEx software provides built-in chamber setting control and control steps for temperature, humidity, timeout, and over-temperature protections while indicating temperature control time, delay time, and standby temperature.

• To ensure consistency in test conditions, the grouping management structure allows all testing channels in the same chamber to enter the temperature control phase at the same time.

• The built-in DI/DO functionality can be connected to a smoke/gas detector, fire extinguisher, and alarms for over-temperature, over-voltage, and open door. The system performs different levels of handling according to the degree of damage, including stopping the test or powering off. Alarm data can be sent remotely via e-mail.

Battery LEx Software

Battery Lab Expert (Battery LEx) is a comprehensive test software platform specifically developed for the Chroma 17010. It offers three key features and a rich set of tools for a variety of applications.

• Group testing: each group can control up to 96 channels and execute up to 50,000 steps

• Variable editing: use data from the external data logger for flexible programming and complex applications

• Chamber integration: real-time monitoring of chamber status and protection mechanisms through DI/DO expansion

Project Browser

• Streamlined management: Easily create and organize up to 500 test plans tailored to specific DUT types or test requirements.

• Intuitive display and real-time editing: Effortlessly browse, inspect, and adjust test plans, DUT specifications, waveform simulation data, and recipe content. Modify parameters on the fly and save them instantly for maximum efficiency.

• DUT database: Establish a central repository for all your DUT specifications, allowing you to quickly map parameters during recipe editing. Use recipe sharing for efficient testing across different projects.

• Operating simulation: Import data points directly from xlsx files to simulate operating conditions. Define time intervals (both equal and custom), output multiplier, and data ranges to create highly realistic test scenarios.

Waveform Simulation Database

DUT Database

Project Browser

Recipe Editor

• Layered structure: Craft intricate test plans with a hierarchical structure including up to 50,000 steps (SR -> MR -> TP)

• Easy creation: Design new recipes from scratch to address a wide range of test applications.

• Quick editing:Combine existing recipes to rapidly build comprehensive test plans.

• Special Settings: Utilize special settings for C-rate, OCV-SOC, Q%, ±V, and variables to create highly customized recipes.

• Variable Settings and Cutoff Conditions: Define up to 20 variables, including 2 variables that can be leveraged across sub-recipes. The 1-100mS transient capture function meticulously records transient changes at the start/end of each step, then defines them as variables for secondary calculation.

Recipe Executor

• Multi-group start

• Various control options: Start, pause, resume, stop, reserved pause, specified start, skip to next step, pause and skip to next step, recipe preview

• Real-time test status: real-time display of test data for single channel and entire groups

• Supports dynamic paralleling for more demanding test requirements

Recipe Executor

Real-time Visualization

• Multi-chart monitoring: View up to 4 independent graphs simultaneously, allowing for comparison of up to 2 test channels per graph

• Graph capture: Use the time freeze function to capture and save test curves

• Multi-axis analysis: Provides dual-Y-axis data display for more comprehensive analysis

Real-time Chart Display

Test Report

• Export modes: choose between manual export or automatic export based on either sub-recipes or time settings.

• Adjustable data precision up to 9 decimal places

• Report types: generate channel-level or step-level reports

• Customization: Freely adjust report items and column orders to tailor the report to your exact needs

Test Report Preview

Chamber Control and System DI/DO Signal Control

• Delay function: set a rest time after reaching the set temperature to ensure consistency between the temperatures of the chamber and the DUTs

• Cycle temperature setting: paired with a data logger, the system can adjust the chamber temperature based on the actual DUT temperature to accurately ensure temperature consistency.

• End-of-test setting modes: includes end temperature control, adjust to the specified temperature, and maintain temperature.

• Dual protection control: over-temperature protection, temperature control timeout protection

• External device control: provides three-color light signal control and relay signal control.

• Synchronized temperature control: automatic sync. mechanism ensures that the chamber temperature control starts only when all channels reach the "temperature control step", ensuring test consistency

• Temperature control inheritance: automatically transfer chamber control to another group upon completion of the main group's test

Chamber Control Settings

Management

• Alert notifications: set up email alerts for warning messages

• Recipe transfer: import/export/move recipes and test plans

• Data management: administrators can set automatic or manual deletion of system data

• Forced global protection: set mandatory protection items for recipes to prevent human error and enhance test safety

Test Plan Import/Export

Lithium Battery Test Applications

Ripple Current Superposition Applications

Verifying the efficiency of lithium-ion battery heating with AC current at temperatures below 0°C (32°F), the conductivity of the electrolyte significantly decreases while the internal resistance increases. This greatly reduces the battery's power capability, which in turn leads to decreased charging efficiency. One way to restore this efficiency is to pre-heat the battery directly with AC current. When selecting the frequency domain of the AC current, it is recommended to prioritize frequencies that do not induce electrochemical reactions in the battery.

Application of Ripple Current Superposition

Evaluating the impact of ripple on lithium-ion battery degradation Ripple mainly originates from inverters in electric vehicles. When the ripple frequency exceeds the frequency range detectable by the battery management system (BMS), and the ripple voltage exceeds the battery's upper voltage limit (e.g., when the ripple frequency is a multiple of the voltage detection frequency of the BMS), it may accelerate battery degradation. This is especially the case under conditions where the internal resistance of the battery cell increases by several factors at low temperatures.

Evaluating the Impact of Ripple on Lithium-ion Battery Degradation

Differential Voltage (dV/dQ)

The key to plotting the d V/ d Q curve is to charge and discharge the battery with a small current (

dV/dQ Test

Direct Current Internal Resistance (DCIR)

The internal resistance of a battery is related to the charge/discharge rate it can withstand. A higher internal resistance results in lower efficiency, increased heat generation, and accelerated aging. The traditional method of measuring AC internal resistance (ACIR) using an 1kHz LCR Meter can evaluate the battery's ohmic resistance (Ro) affecting the instantaneous power output, but it cannot assess the polarization resistance (Rp) produced during electrochemical reactions. In contrast, DCIR measurement includes ACIR while also more closely reflecting actual polarization effects in automotive battery applications involving continuous current.

The Chroma 17010 has two programmable DCIR test modes, and – with the variable calculation function - can automatically obtain test results that meet the IEC 61960 standard.

• DCIR (1) is based on the voltage difference caused by one current change

• DCIR (2) is based on the voltage difference caused by the change between two currents

Li-ion battery Equivalent Circuit Model

DCIR Test (1)

DCIR Test (2)

Hybrid Pulse Power Characteristic (HPPC)

The Chroma 17010 features a flexible editing program that can compile HPPC test steps, as defined by the U.S. Council for Automotive Research (USCAR) for evaluation of EV battery performance. The purpose is to obtain the open circuit voltage, ohmic resistance (Ro), and polarization resistance (Rp) of a specific depth of discharge within the battery's operating voltage range using the specified test methods. It establishes a functional relationship between the depth of discharge and the charge/ discharge peak power, serving as an indicator for evaluating the battery cell's aging and output power capacity.

HPPC Test

Battery Capacity

Battery capacity can be obtained by integrating current over time, from the start of charging/discharging until the cutoff condition is reached. Common test items include current ratio and temperature characteristics. Comparing the results allows you to analyze performance differences between products. The test system's highly precise current/voltage measurement and fast sampling rates enable you to distinguish differences in battery cell capacity with a high degree of accuracy.

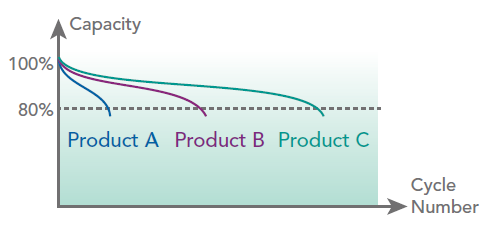

Battery Cycle Life

Cycle life is one of the most important test items for batteries. Based on experimental objectives, this test subjects the battery through repeated charge and discharge conditions until the capacity falls to 80%, and then calculates the number of cycles. The cycle life test can be used to evaluate battery performance or define proper conditions of use.

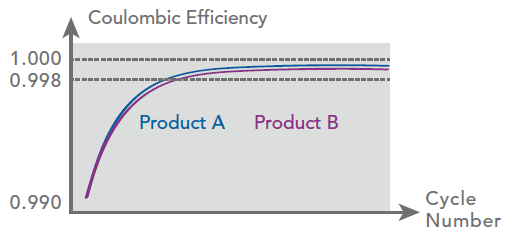

Coulombic Efficiency (CE)

CE is calculated by fully charging and discharging the battery and then measuring the ratio of the total charge put into the battery. The Chroma 17010's best-in-class precision and stability allow you to easily identify batteries with superior characteristics. Through accurate CE testing, battery life can be estimated using fewer cycles, saving time and resources in the evaluation process.

Coulombic Efficiency Test

Charge & Discharge Rate

This test is commonly used to evaluate how well a battery maintains its voltage platform and capacity when charged and discharged at different rates. It is frequently applied in the material development process, to adjust the proportion of active materials for instance, and to verify the performance of power batteries during rapid charge and discharge cycles.

Charge & Discharge Rate

Optional Calibration System and System Accessories

Ripple Current Superposition Test System

Chroma's Ripple Current Superposition Test System consists of a programmable high-frequency AC tester, an AC/DC decoupling module, and a DC charge/discharge tester. The independent AC and DC loops can be applied to various charge and discharge modes, with minimal impact on the cut-off judgment of DC charge and discharge tests, aiding in cycle life comparison.

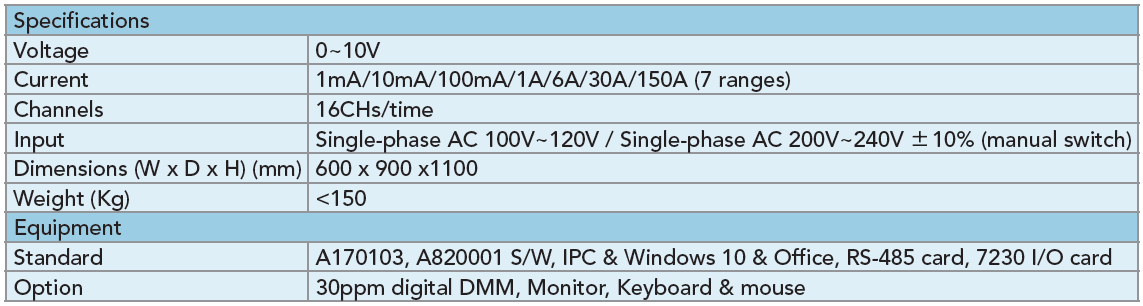

Battery Cell Testing Data Logger

The Chroma A172013 multi-channel voltage and A172014 multi-channel temperature data loggers can serve as auxiliary channels for the 17010 system, providing real-time monitoring of DUT data during charge and discharge tests. This data can then be integrated into the test report via the Battery LEx software, where you can also set upper limit protections to ensure test safety.

• Each channel adopts independent 24-bit ADC sampling

• Equipped with cold junction compensation function

• Can be used as a standalone unit or connected to voltage or temperature modules, expandable up to 128 channels

Note:

*1: A172013 and A172014 modules can be integrated and used simultaneously.

*2: The accuracy specification does not include errors caused by the testing cables, under the condition of 100ms sampling and 23±5℃.

*3: The sampling time is for the single unit specification and does not include data integration and transmission.

Battery Cell Test System Auto Calibrator

The Chroma A170103 is an automated calibration and verification system equipped with various high-precision standard components. It features programmable control for multi-channel calibration tasks and is suitable for products in the Chroma 17010 series with currents up to 150A. This system ensures the equipment maintains high accuracy and traceability, forming an integral part of Chroma's high-precision test solutions.

• Consistent and standardized inspection: scientific approach minimizes human error and test variability

• Efficient calibration and verification: reduces workforce requirements and saves costs

• Automated report generation: ensures traceability and easy management of maintenance records

Environmental and Rack Specifications