As market demand for higher power density increases, it has become critical for battery test equipment to mitigate safety risks by providing safe and responsive protection during testing. Real-time monitoring and auto protection mechanisms are features that allow for safe testing of higher density battery packs. The model 17040 high power regenerative battery pack test system newly introduced by Chroma supports three layers of automated real-time monitoring and protection as well as meets the dynamic fast response test standards for battery pack testing.

The first layer of auto protection downloads the charge/discharge test sequences to the hardware’s protection and cutoff settings in order to prevent any charging/discharging errors in the event the computer goes down. The second layer of protection reads and analyses parameter data received from a BMS or data logger, defines the data in the protection and cutoff settings, and provides real time monitoring of the battery pack’s internal status. The third layer of protection actively triggers the external protection hardware that measures the voltage and/or temperature of the battery pack and switches off the output main contactor to avoid damage to the battery pack or injury to users if the first and second layer of protection fails. Moreover, real-time data feedback from the BMS can modify test conditions immediately to meet the battery pack’s dynamic fast response test standards.

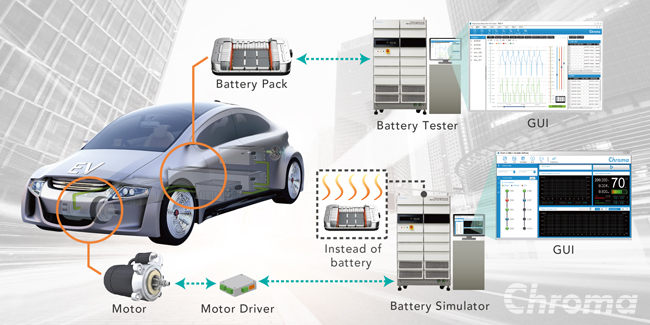

In recent years, Chroma ATE has been aggressive in developing optimal test solutions for battery cells, battery modules, and battery packs.

The key features of the 17040 test system are listed as below:

▲Regenerative Battery Pack Test System

- Max. output power range: 60kW/120kW/180kW/250kW/300kW

- Max. voltage/current output spec.: 1000V / 750A. Full power or full current output when voltage >700V.

- Measurement accuracy <0.05%FS. Voltage/current auto range function with test accuracy higher than standard.

- Fast current slew rate (10% to +90%):<2msec, fast charging/discharging switching time (-90% to +90%): <5msec

- Quadratic integral equations implemented in firmware with high sampling rate (50kHz) to increase the accuracy of capacity calculation for dynamic testing.

- Fastest test report data sampling rate: 10ms (Waveform mode: 1ms)

- Energy regenerative function, efficiency > 90%, PF > 0.95, THD<5%

- Uses SiC MOSFET to increase switching frequency, reduce equipment temperature rise, extend the equipment lifespan, and improve accuracy and stability.

- Support simultaneous battery charge/discharge and battery simulator function for users to switch freely.

- Compliance with CE mark testing and certification

▲Switch for Dual Mode Application

With over 30 years of experience in test and measurement instrumentation, Chroma is able to provide a wide variety of test solutions for power and storage batteries. These include: regenerative battery pack test systems for battery cells, battery modules, and battery packs; BMS test systems; battery pack EOL auto test systems; battery simulators; and super capacitors. These solutions are in use worldwide by manufacturers and third party laboratories. For any questions regarding these battery test solutions, please provide your contact information and we will reach out to you for further service.

| Battery Pack / Module Test Solution |