What is non-invasive analysis?

The analysis of lithium-ion battery cell degradation can be classified into invasive and non-invasive methods, with non-invasive analysis offering the following advantages: (1) Evidence of battery degradation can be retained in its entirety; (2) Minimizes the effect of external factors on the battery state and introduction of new variations; (3) Allows for identification of known battery parameters through specific measurement instruments and systematic classification of battery aging mechanisms. Therefore, whether in evaluating battery material performance, selecting batteries, or studying battery degradation, non-invasive analysis has seen wide adoption and is known to yield significant results.

Typical non-invasive deterioration analysis method: Differential Voltage-Incremental Capacity Analysis (DV-ICA)

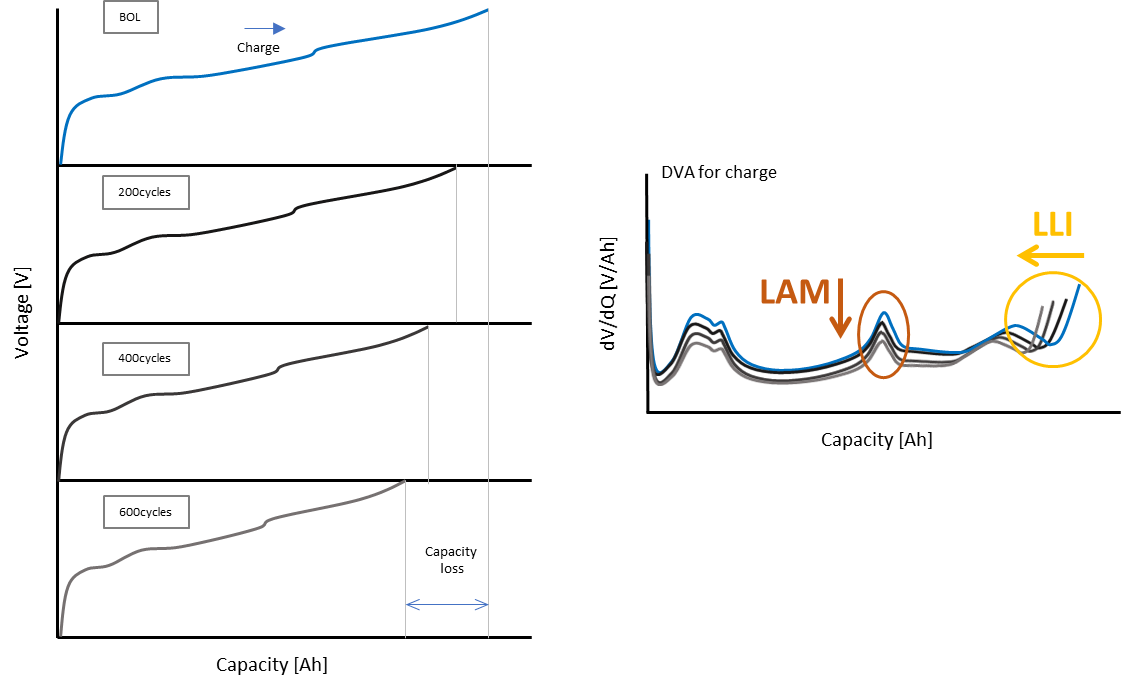

One of the most employed methods for non-invasive battery degradation analysis is the use of Differential Voltage (DV) and Incremental Capacity (IC). This approach typically involves alternating DV-IC degradation analysis tests after a specific number of ageing cycles. Polarization effects are minimized through extremely low-rate charge-discharge currents (~C/25) in order to obtain an approximately ideal OCV-Q relationship, and the DV and IC curves are plotted using first-order differentials, as shown in Figure 1. DV and IC curves, along with changes in their peak areas (PA), can indicate the degree of battery aging. The degree of shift in the X-Y axis parameters can be used to evaluate the battery's degradation mode (DM), i.e. the degree of loss of lithium inventory (LLI) and loss of active material (LAM), allowing estimation of potential aging mechanisms, as shown in Table 1[4] below. Additionally, the high precision of the DV curve enables effective identification of the phase changes of the positive and negative electrode in the entire battery at specific potentials. This helps to determine the state of degradation without needing a reference electrode for verification.

▲(Figure 1) Schematic diagram of DVA curve change under different cycle times of battery

▲(Table 1) Relationship between changes in IC-DV curves and corresponding degradation indicators, potential

Challenges of Using Differential Voltage-Incremental Capacity Analysis (DV-ICA)

Efficiently obtaining precise DV-IC curves involves overcoming the following challenges: 1. The charge-discharge test instrument lacks higher voltage and current precision and accuracy. 2. The DV-IC curve and its characteristic peaks must be clearly identified through a smoothing algorithm, posing a risk of data over-modification and distortion. 3. Creating smoothing algorithms for batteries with different material systems is time-consuming.

Chroma's solutions

For the simplest and fastest resolution to the challenges mentioned above, utilizing high-precision measurement equipment is undoubtedly the best approach. In addition to stabilizing the current output throughout the whole process to ensure ultra-high accuracy in long-term voltage and current measurements, it is also important to minimize the impact of temperature and internal measurement noise to obtain clearly recognizable DV-IC curves and characteristic peaks. Chroma's newest entry in its 17010 Series, Model 17208M-5-12C, is an ultra-high precision charge-discharge tester specifically built for this application. With measurement precision reaching up to <±0.001% of F.S., this system provides a highly accurate and efficient solution for battery degradation assessment.

▲DV-IC Curve Test Results with 17208M-5-12C

To learn more about the features and specifications of Chroma 17010 Series 17208M-5-12C Ultra High Precision Battery Cell Charge and Discharge Tester, please refer to the following official website link and leave your request and contact information, we will be glad to serve you.

| Chroma 17010 Battery Reliability Test System |

References:

[1] Carlos Pastor-Fernandez, Kotub Uddin, Gael H. Chouchelamane, W. Dhammika Widanage, Journal of Power Sources 2017;360: 301-318

[2] Gyuwon Seo, Jaeyun Ha, Moonsu Kim, Journal of Energy Chemistry 2022; 67: 663–671

[3] Peter Keil, and Andreas Jossen J. Electrochem. Soc. 2017;164:A6066-A6074

[4] Matthieu Dubarry, Cyril Truchot, Bor Yann Liaw, Journal of Power Sources 2012; 219:204-216