The Chroma 19311 Surge Tester Series is a powerful tool for testing the insulation quality of lead-acid battery cells before electrolyte injection. With its ability to apply high-voltage pulses, it enables accurate assessment of the insulation quality between the positive and negative plates, as well as the insulation quality of laser-cut trims on metal film resistors. The 19311 series has a maximum pulse output voltage of 6kV, fourwire voltage measurement, and a highspeed sampling rate of 200MHz, suitable for surge testing of battery cells as well as metal film resistors. Users can select either the single-channel tester (Model 19311) or the multi-channel scan tester (Model 19311-10) to meet their specific testing needs.

The 19311-10 model has 10 channels and can switch between multiple battery cells using a scan test method, with a single unit capable of testing up to 9 battery cells at a time. The 19311-10 can support up to 25 channels for testing up to 24 battery cells in a sequence by connecting with A190362 external scanning box. Quickly scanning and testing multiple battery cells at a time leads to significant savings on testing time and labor costs, making this instrument particularly suitable for use on production lines to increase throughput.

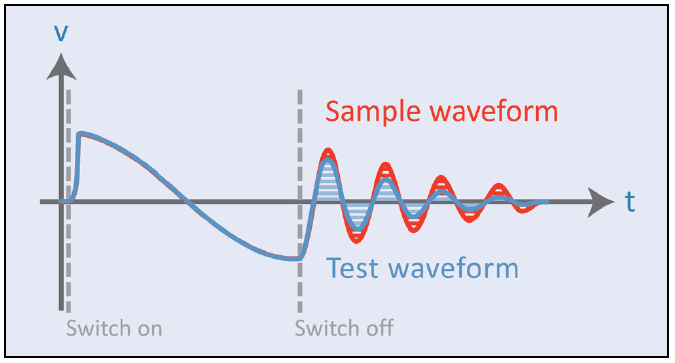

The main purpose of using high-voltage pulses to test the positive and negative plates of lead-acid battery cells before electrolyte injection is threefold: to detect the distance and quality of the insulation between the positive and negative plates in battery cell, to verify the presence of a separator and a short circuit between the positive and negative plates, so as to find out inferior or bad battery cells. The 19311 Series analyzes the insulation quality of battery cells using their internal inductance and high-voltage osci l lation damping.

The primary objective of testing the resistance of metal film resistors with highvoltage pulses is to assess the insulation distance and quality of the laser trimming, as well as any short circuit risks, in order to identify inferior or defective products. The Chroma 19311 Series applies short and low-energy high-voltage pulses to the paralleled metal film resistors to detect any flaws in their internal insulation quality.

Therefore, by utilizing the impulse testing capabilities of the Chroma 19311 Series, the insulation quality of lead-acid battery cells, metal film resistors, and other components can be significantly improved, resulting in products that are highly reliable and suitable for longterm use.